Snow Plowing: 5 Expert Tips 2025

Understanding Snow Management

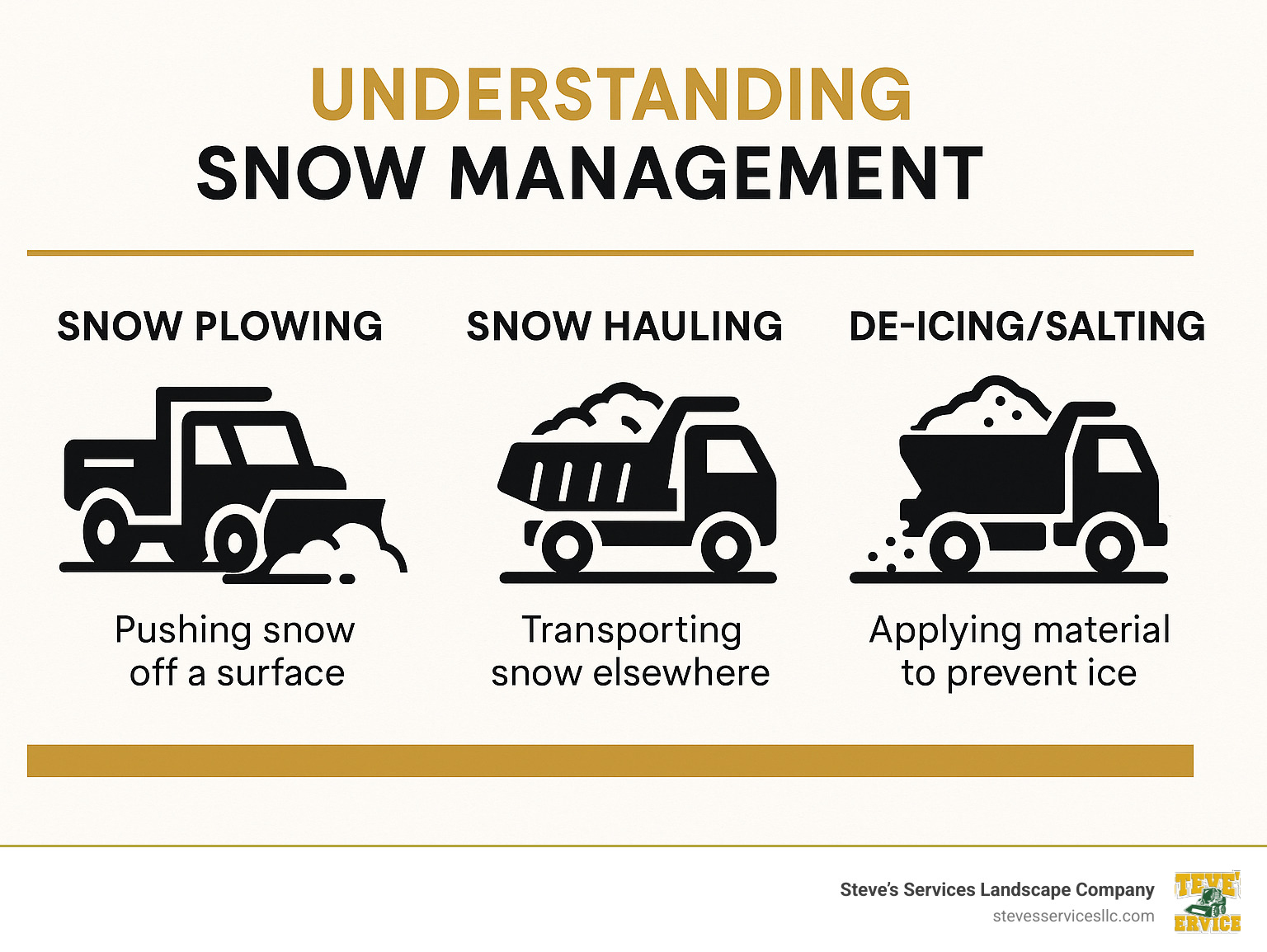

Snow plowing is the foundational process of using a vehicle-mounted blade to push snow from a surface, clearing roads, driveways, and parking lots to make them safe and accessible. However, true winter preparedness goes far beyond a single push of the plow. Comprehensive snow management is a strategic, multi-faceted service designed to ensure safety, minimize liability, and maintain business continuity throughout the harshest winter months.

Winter weather in Massachusetts brings a unique set of challenges for homeowners and commercial property managers. Heavy, wet snow from powerful Nor’easters can strain roofs and topple trees, while rapid freeze-thaw cycles create treacherous black ice on untreated surfaces. Inadequate snow management doesn’t just mean inconvenience; it can lead to slip-and-fall accidents, costly property damage, and significant business disruptions. For a commercial property, an inaccessible parking lot means lost revenue and frustrated customers. For a residential community, it can mean delayed emergency services.

That’s where a professional strategy comes in. This guide will help you understand the full scope of managing winter’s impact, from the initial response to a storm to the final touches that ensure surfaces are clear and safe. At its core, professional snow management involves three key services:

- Snow Plowing: The immediate response to snowfall, focused on clearing pathways and parking areas by pushing snow into designated piles (snow stacks) on-site.

- Snow Hauling (or Snow Removal): When on-site snow storage is limited, or piles become dangerously large, this service involves using heavy equipment like loaders to load snow into dump trucks and transport it off-site.

- De-icing and Salting: A critical step for safety, this involves applying materials like rock salt or liquid brine to melt remaining ice and snow, preventing it from bonding with the pavement and creating a lasting, slip-resistant surface.

With over 25 years of experience in landscape management, I’m Steve Sylva, owner of Steve’s Services. My team and I specialize in providing these comprehensive snow management solutions for homes and businesses throughout the greater Boston area. We understand the local weather patterns and the specific needs of Massachusetts properties, ensuring your outdoor spaces remain safe, accessible, and functional all winter long.

The Evolution and Equipment of Snow Removal

The story of snow plowing is one of human ingenuity meeting winter’s challenges head-on. What started as simple, animal-powered tools has transformed into today’s sophisticated, technology-driven snow management systems that keep our communities moving through the harshest storms.

The first snowplow appeared much earlier than most people realize. Back in 1792, residents of New Hampshire were already using horse-drawn wedge plows to clear paths. Picture a sturdy team of horses pulling a heavy wooden V-shaped contraption, slowly but surely carving out a passage for wagons and travelers. These early plows were a testament to community resilience but were slow, labor-intensive, and limited by the endurance of the animals.

Railways, the economic arteries of the 19th century, quickly adopted the technology. By the 1840s, “snow-clearers” were being patented across the US to keep tracks clear and trains running on schedule. Some passenger trains in Lower Austria even carried small wedge plows mounted directly on the front, a proactive measure to handle unexpected drifts. This was a crucial step, as a blocked rail line could halt the flow of goods and people for days.

The true turning point came in 1913 when Good Roads Machinery in Kennett Square, PA, built something revolutionary: the first snowplow designed specifically for motor equipment. This wasn’t just an adaptation of a horse-drawn tool; it was purpose-built for the power and speed of the automobile age. This innovation paved the way for companies like Frink Snowplows (around 1920) and Norway’s Øveraasen (1923) to begin developing the truck-mounted solutions that form the bedrock of modern winter road maintenance.

Today’s snow plowing arsenal is vast and impressive. We use a range of specialized equipment, each chosen for its specific strengths. Straight-blade plows offer versatility for general clearing, while V-plows are essential for breaking through deep, heavy drifts. For moving large volumes of snow efficiently, box plows (also known as snow pushers) are best. These are supported by heavy graders for scraping packed ice on major roadways, powerful loaders for stacking and hauling, and precisely calibrated salt spreaders for ice management. This complete toolkit allows professionals to tackle any winter scenario, keeping Massachusetts communities safe and accessible. For more details on the equipment we use, check out our Best Snow Removal Equipment page.

From Horse-Drawn to High-Tech

The leap from that first motor equipment plow in 1913 to today’s high-tech machines is nothing short of amazing. Early innovations focused on mechanical improvements. Underbody scrapers, for instance, were developed to mount between the front and rear axles of a truck, using immense downward pressure to shear away stubborn, compacted snow and ice that surface plows couldn’t touch. This was a game-changer for clearing city streets and residential driveways down to the pavement.

But the real magic is in today’s modern plows, which are as much about data and technology as they are about steel. We’re talking about integrated GPS technology that allows for route optimization, real-time crew tracking, and detailed post-storm reporting for clients. Operators benefit from head-up displays that project vital information like speed and blade position onto the windshield, allowing them to keep their eyes on the road. Infrared cameras can cut through blinding whiteout conditions, revealing road edges and obstacles that would otherwise be invisible. On highways, massive articulated plows can clear multiple lanes in a single pass—a common sight on Massachusetts interstates during major storms.

These modern advancements are not just flashy gadgets; they are critical tools for safety and efficiency. When visibility drops to near zero and temperatures plummet, technology that helps our operators work smarter, not just harder, makes all the difference. It allows for more precise application of de-icing materials, reducing environmental impact and cost, and ultimately keeps communities connected and safe.

Matching the Machine to the Job

Effective and cost-efficient snow plowing is all about deploying the right tool for the right job. Just as a carpenter has more than just a hammer, a professional snow contractor has a diverse fleet to handle any situation with precision.

For most residential driveways and small commercial lots, pickup trucks with straight-blade attachments are the workhorses. They are nimble, reliable, and can steer tight spaces with ease. As properties get larger, service trucks with heavier-duty plows and larger salt spreaders take over, offering more power and capacity while maintaining good maneuverability for medium-sized lots and access roads.

When we tackle large commercial properties—like shopping centers, industrial parks, or hospital campuses—we bring out the heavy artillery. Front-end loaders and skid-steers equipped with large box plows can move massive amounts of snow far more quickly and efficiently than a standard pickup. These machines are essential for clearing vast parking lots and stacking snow into tall, consolidated piles, maximizing available space.

Pedestrian safety is just as important as vehicle access. For sidewalks, walkways, and building entrances, we use specialized equipment. This can include ATVs for sidewalks fitted with small plows or rotary brooms, as well as powerful compact snow blowers. These smaller machines ensure that foot traffic can move safely, which is crucial for businesses that need to remain open and accessible to customers and employees during and after a storm.

Our team at Steve’s Services understands that this careful equipment matching is critical for both performance and cost-effectiveness. We’ve built our reputation on analyzing each property’s unique layout and needs to create a custom-custom operational plan. Whether it’s a cozy residential driveway in Melrose or a sprawling corporate campus in Burlington, we bring the right machine for the job. Learn more about our comprehensive approach at Commercial Snow Plowing.

| Plow Type | Description | Best Use Cases | Pros | Cons |

|---|---|---|---|---|

| Straight Blade | A single, flat blade that can be angled to push snow left or right. The most common type of plow. | Residential driveways, small-to-medium commercial lots, all-purpose clearing. | Versatile, cost-effective, excellent for back-dragging snow away from garage doors. | Less effective in very deep or heavy snow compared to a V-plow. |

| V-Plow | Two independently controlled wings that form a V-shape to break through deep snow, or can be configured as a straight blade or a scoop. | Initial path clearing in deep snow, highway plowing, breaking through frozen banks. | Extremely versatile, powerful in deep conditions, can scoop and stack snow. | More expensive, heavier, and more complex mechanically than a straight blade. |

| Box Plow | A large rectangular containment box with side wings that pushes snow forward without leaving windrows. | Large, open parking lots (e.g., malls, distribution centers), industrial properties. | Extremely efficient for moving large volumes of snow quickly, reduces number of passes needed. | Not suitable for small or tight areas, cannot be angled, not ideal for public roads. |

| Loader/Skid-Steer | Heavy equipment like front-end loaders or skid-steers fitted with large pusher boxes or buckets. | Snow stacking, loading snow for hauling, clearing large commercial sites. | Best power for moving and lifting heavy snow, essential for managing large accumulations. | Slower travel speed, requires a skilled operator, higher operational cost. |