Frozen Sprinkler Backflow Valve: 7 Essential Fixes for 2025

Why a Frozen Sprinkler Backflow Valve Is a Serious Emergency

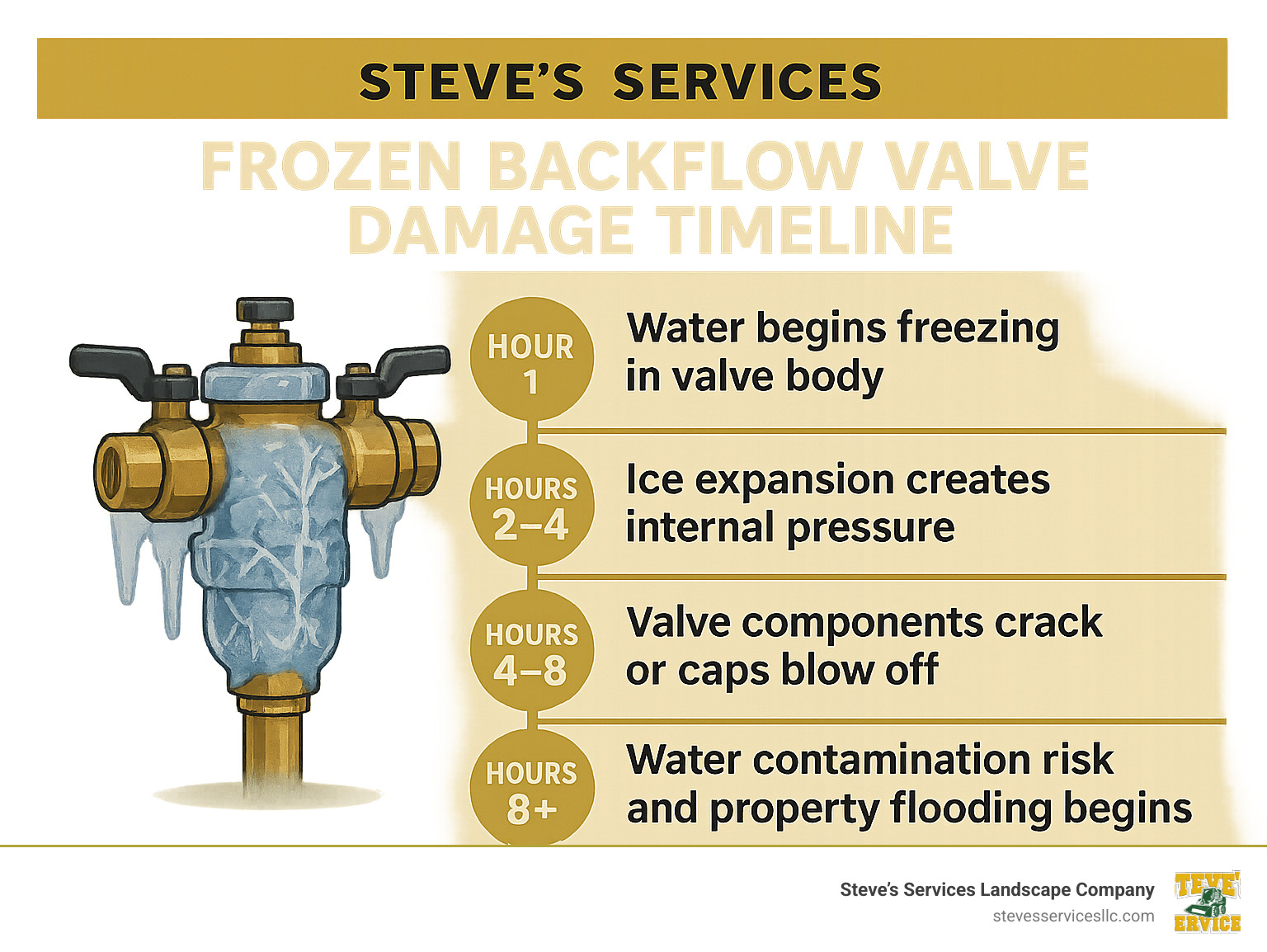

A frozen sprinkler backflow valve can turn from a minor inconvenience into a costly disaster in just hours. When water freezes inside your backflow preventer, it expands by roughly 9% of its original volume – enough force to crack metal components, blow off valve caps, and create dangerous contamination pathways between your irrigation system and drinking water supply.

The physics behind freeze damage are both simple and devastating. Water is one of the few substances that expands when it solidifies, and this expansion creates pressures exceeding 30,000 pounds per square inch. Even the strongest bronze and brass valve bodies can’t withstand this kind of internal pressure, which is why we see catastrophic failures during sudden temperature drops.

In Massachusetts, where winter temperatures can plummet from 40°F to below freezing in just a few hours, backflow preventers face some of the most challenging conditions in the country. The combination of rapid temperature changes, wind chill effects, and prolonged sub-freezing periods creates a perfect storm for irrigation system failures.

Immediate Actions for a Frozen Backflow Valve:

- Turn off the main water supply to the irrigation system immediately

- Open test cocks and drain valves to relieve pressure (if accessible)

- Do not attempt to thaw with heat – this can cause rapid pressure changes

- Document damage with photos for insurance purposes

- Call a certified backflow tester for professional assessment

- Protect the area from additional freeze exposure

The risks go far beyond repair costs. Recent freeze events in typically warm climates like Houston and Phoenix have caused thousands of backflow preventer failures, leading to property flooding, contaminated water supplies, and expensive emergency repairs ranging from $200 to over $7,500 based on internet research.

What makes these emergencies particularly dangerous is the contamination risk. Your irrigation system contains water mixed with fertilizers, pesticides, herbicides, and soil bacteria – substances you’d never want in your drinking water. When a backflow preventer fails due to freezing, it creates a direct pathway for these contaminants to enter your home’s potable water supply.

The economic impact extends beyond immediate repair costs. Property damage from flooding can affect foundations, landscaping, hardscaping, and even neighboring properties. Insurance claims for freeze-related irrigation damage often involve complex coverage questions, and many homeowners find their policies don’t cover preventable maintenance issues.

I’m Steve Sylva, owner of Steve’s Services in Malden, MA, and I’ve helped hundreds of property owners deal with frozen sprinkler backflow valve emergencies over my 25+ years in the landscape industry. Understanding the immediate steps and long-term prevention strategies can save you thousands in damage and protect your family’s water safety.

Our service area includes Burlington, Danvers, Everett, Lynnfield, Medford, Melrose, North Reading, Reading, Revere, Saugus, Stoneham, Winchester, Woburn, Malden, and Wakefield – all communities that face serious freeze risks during New England winters. Each of these areas has specific municipal requirements for backflow prevention, and we work closely with local health departments to ensure compliance.

The timing of freeze events often catches homeowners off guard. Early season freezes in October or November frequently occur before irrigation systems have been properly winterized. Late season cold snaps in March or April can damage systems that have been reactivated too early. Understanding these patterns and preparing accordingly is essential for protecting your investment.

Glossary for frozen sprinkler backflow valve:

What a Backflow Preventer Does & Why It’s Non-Negotiable

Your irrigation backflow preventer is the one device standing between lawn chemicals and the water your family drinks. When municipal pressure suddenly drops—think water-main breaks or fire-department use—it creates a vacuum that can pull pesticide-laden irrigation water backward through any cross-connection. The preventer stops that reverse flow, keeping contaminants out of your taps and out of the public water system.

Massachusetts codes require every residential sprinkler system to have a functioning, annually tested preventer, and municipalities from Everett to Winchester can levy steep fines for non-compliance.

Anatomy in 60 Seconds

• Shut-off valves – isolate the device for service.

• Test cocks – tiny ports used during yearly certification and winter drainage.

• Check assemblies – spring-loaded parts that let water move forward but slam shut against backflow.

• Relief port – discharges water if internal pressure rises abnormally.

Knowing these parts lets you spot freeze damage fast and explain issues to a certified tester.

How It Works in an Irrigation System

During normal operation, higher city pressure pushes water through the checks toward your sprinkler heads. If that pressure reverses for even a second, the checks shut and the relief port opens to break any siphon—no contaminated water can reach your kitchen sink.

Bottom line: no working backflow preventer, no safe drinking water. That’s why annual testing isn’t optional, and why a frozen, cracked valve is far more than a plumbing annoyance.

Frozen Sprinkler Backflow Valve: Causes, Warning Signs & Immediate Risks

Water expands about 9 % when it freezes—enough to create pressures above 30,000 psi, more than enough to split bronze. Because backflow preventers sit above ground, they feel every New England wind chill. One overnight plunge from 40 °F to the teens can blow a valve cap into the neighbor’s yard and create an instant geyser.

The bigger danger is invisible: a cracked valve lets fertilizer-tainted water flow straight into your home’s pipes the next time municipal pressure drops.

Quick Checklist – Is Yours Damaged?

• Water spraying or misting from the device

• Missing or tilted bonnet/cap

• Hairline cracks in the brass body

• Constant drip even with the system off

• Sprinkler zones showing unusually low pressure

First-Hour Emergency Steps

- Close the upstream shut-off valve immediately.

- Open test cocks to relieve pressure—stand clear of any spray.

- Take photos for insurance documentation.

- Gently cover the unit with a tarp or blanket to slow further freezing; do not use open-flame torches or space heaters.

- Call a certified backflow tester. Massachusetts law prohibits DIY repairs on these devices.

Need help fast in Malden, Medford, or any town we serve? More info about Irrigation System Repairs Near Me

Professional Repair Process & Average Cost Range

When your frozen sprinkler backflow valve needs professional attention, the repair process is far more complex than most homeowners realize. As a certified backflow tester with over 25 years of experience, I can tell you that proper repairs require specialized knowledge, certified testing equipment, and strict adherence to Massachusetts health codes.

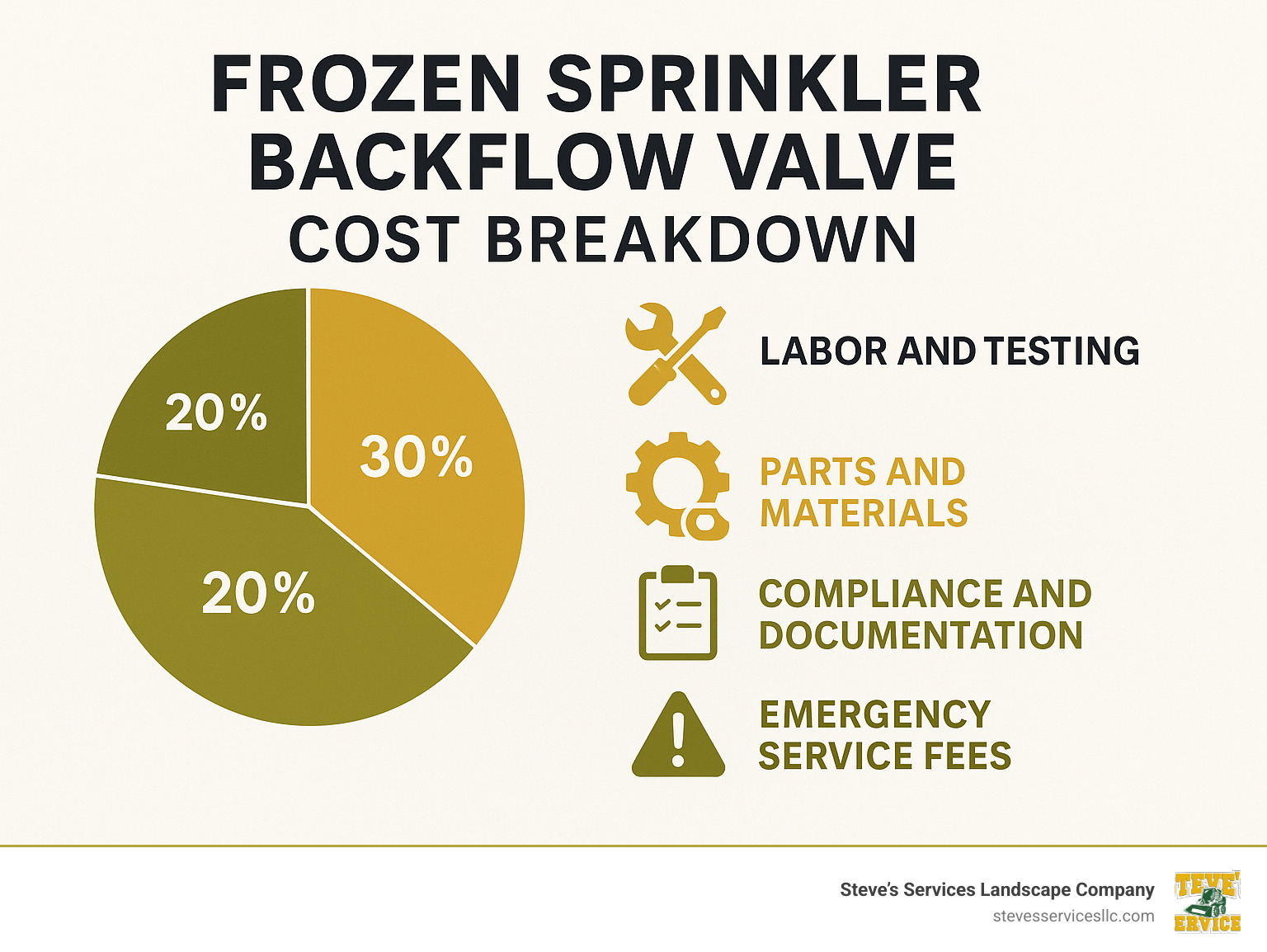

The journey starts with a thorough inspection where we assess both visible damage and internal component failure. What looks like a simple cracked cap often reveals extensive internal damage to check valves, springs, and sealing surfaces. We use calibrated pressure testing equipment to identify every compromised component – something that’s impossible to do with visual inspection alone.

Component replacement comes next, and here’s where many property owners get sticker shock. Backflow preventers use precision-engineered parts that must meet strict ASSE (American Society of Sanitary Engineering) standards. We can’t use generic hardware store parts – every component must be manufacturer-approved and certified for potable water protection.

The pressure testing and calibration phase ensures your device actually works as intended. We test at multiple pressure points, verify proper check valve operation, and confirm that relief ports function correctly. This isn’t a quick process – proper testing takes time and can’t be rushed.

Compliance documentation is the final critical step. Massachusetts requires detailed reports for all backflow preventer repairs, and these documents must be filed with local health departments. Without proper paperwork, your repair isn’t legally complete, and you could face fines during future inspections.

Based on internet research (not Steve’s Services actual pricing), repair costs vary dramatically depending on damage severity. Minor repairs involving seals and small components typically range from $200 to $600, while major repairs requiring valve body replacement or multiple component failure can cost $400 to $1,200. Complete replacement of the entire backflow assembly ranges from $600 to $2,500, with emergency service calls adding $300 to $900 to your total bill.

The real financial pain often comes from hidden costs that catch homeowners off guard. We’ve seen situations where a $400 backflow repair turned into a $3,000 project once you factor in water damage to landscaping, emergency plumbing calls, and temporary water service disruption. Property flooding from a blown-off valve cap can destroy expensive plantings and hardscape features that took years to establish.

Insurance considerations add another layer of complexity. Many homeowners find their standard policy doesn’t cover freeze damage to irrigation equipment, especially if the system wasn’t properly winterized. Always check your coverage before assuming repairs will be covered.

When to Call a Licensed Pro vs. Utility Company

Here’s something many homeowners don’t understand: backflow preventer repairs are never DIY projects. Massachusetts law requires certified backflow testers to perform all repairs, testing, and documentation. Attempting repairs yourself isn’t just illegal – it’s dangerous and could result in serious contamination of your drinking water supply.

The decision between calling a licensed contractor versus your utility company depends on the situation. Contact your water utility immediately if you suspect contamination has already occurred, notice unusual taste or odor in your drinking water, or observe abnormally low municipal pressure throughout your neighborhood. They have the authority to issue boil-water advisories and can test your water supply for safety.

Call a certified backflow tester for all device repairs, annual testing requirements, and compliance documentation. We work directly with local health departments and understand the specific requirements for your municipality. In our service areas including Malden, Medford, and Winchester, we maintain relationships with health inspectors and can expedite the approval process for emergency repairs.

Contamination incidents require immediate notification to your local health department regardless of who performs the repair. This isn’t optional – it’s a legal requirement that protects public health and ensures proper documentation of the incident.

Preventing the Next Freeze: Proven Winterization & Upgrade Strategies

Professional winterization costs far less than a mid-winter emergency. Our standard service includes:

• Full drain-and-blowout with commercial-grade compressors that clear every drop (shop compressors can’t).

• Confirming an accessible isolation valve upstream of the preventer—adding one if it’s missing.

• Installing or inspecting an insulated cover. In our climate we recommend ASSE-1060 rated heated enclosures for the best protection; basic blankets work only for mild snaps.

• Optional heat tape or Wi-Fi freeze sensors for properties that need early spring watering or extra peace of mind.

| Protection Method | Internet Cost Range* | Best For |

|---|---|---|

| Insulation blanket | $50 – $450 | Short frosts, shoulder season |

| Heat tape | $100 – $900 | Frequent cold snaps |

| Heated enclosure | $300 – $2,400 | Long, sub-zero periods |

*Average pricing based on publicly available data—not Steve’s Services’ rates.

Fall Checklist (Do This by Mid-October)

- Tag shut-off location so anyone can find it in the dark.

- Turn test cocks to a 45° angle for drainage.

- Schedule blow-out and, if due, annual test in one visit.

- Photograph valve positions for easy spring startup.

Spring Startup in Brief

Open the isolation valve slowly while watching for leaks, then run each zone for a minute. Any moisture around the preventer means it didn’t survive the winter—call a pro before using the system.

Choosing Freeze-Resistant Technology & Smart Sensors

Tired of playing defense every winter? Newer freeze-resistant backflow preventers have sacrificial relief plugs that pop before the main body cracks—often a $20 part instead of a $2,000 replacement.

Pair that hardware with smart freeze sensors that text your phone when temps around the valve dip below a chosen threshold. Advanced models integrate with home-automation systems and keep monitoring during power outages.

Before upgrading, confirm you have a proper isolation valve. Retrofitting one requires a licensed plumber and may need a permit, but it makes every future winterization faster, cheaper, and safer.

Frequently Asked Questions about Frozen Sprinkler Backflow Valves

What happens if I ignore a frozen backflow preventer?

You risk contaminating your drinking water and racking up thousands in property damage. Massachusetts health departments can issue fines of $500 – $5,000 for cross-connection violations, and insurance may deny claims if the failure was preventable.

Can I just wrap the valve with a towel?

Maybe for a single light frost, but not for a January nor’easter. For sustained sub-freezing weather, use a rated insulated cover or heated enclosure.

How often should the device be tested after a repair?

State law says once a year. After major freeze repairs, schedule a follow-up test within 30 days, then return to the normal annual cycle.

Keeping good records of those tests protects your water supply—and your wallet—if future problems arise.

Conclusion

When you find a frozen sprinkler backflow valve, you’re not just looking at a broken piece of equipment – you’re facing a potential threat to your family’s drinking water and your property’s safety. That 9% expansion of freezing water packs enough punch to crack metal valve bodies, blow off caps, and create contamination pathways that could affect your entire water supply.

The good news? Most freeze damage is completely preventable with proper winterization and professional maintenance. Understanding the warning signs, knowing how to respond in an emergency, and implementing proven prevention strategies can save you thousands in repair costs and protect what matters most – your family’s health.

Over my 25+ years serving Massachusetts communities like Malden, Winchester, and Reading, I’ve seen too many homeowners learn about backflow protection the hard way. The pattern is always the same: a sudden cold snap hits, water freezes in an unprotected valve, and what should have been a simple winterization becomes an expensive emergency repair.

But I’ve also seen the peace of mind that comes with proper preparation. Homeowners who invest in professional winterization, quality insulation covers, and regular maintenance rarely face these emergencies. They sleep better knowing their water is safe and their systems are protected.

The investment in prevention – whether it’s professional blowout services, insulated covers, or upgraded freeze-resistant technology – always costs less than emergency repairs. And when you factor in the potential health risks and property damage from contaminated water or flooding, the choice becomes even clearer.

Don’t wait for the next freeze warning to think about your backflow preventer. Whether you need emergency repair services or want to protect your system before winter arrives, professional expertise makes all the difference. More info about Irrigation Systems

Your family’s water safety and your property’s protection are worth the investment in doing things right the first time.