How to get small excavation jobs: 5 Profitable Steps

Why Small Excavation Jobs are the Perfect Entry Point for New Contractors

How to get small excavation jobs starts with understanding that the construction industry offers tremendous opportunities for entrepreneurs willing to start focused and grow strategically. The excavation sector is experiencing steady growth, with more than 85% of people using the internet to find local excavating and paving companies, creating abundant opportunities for new businesses.

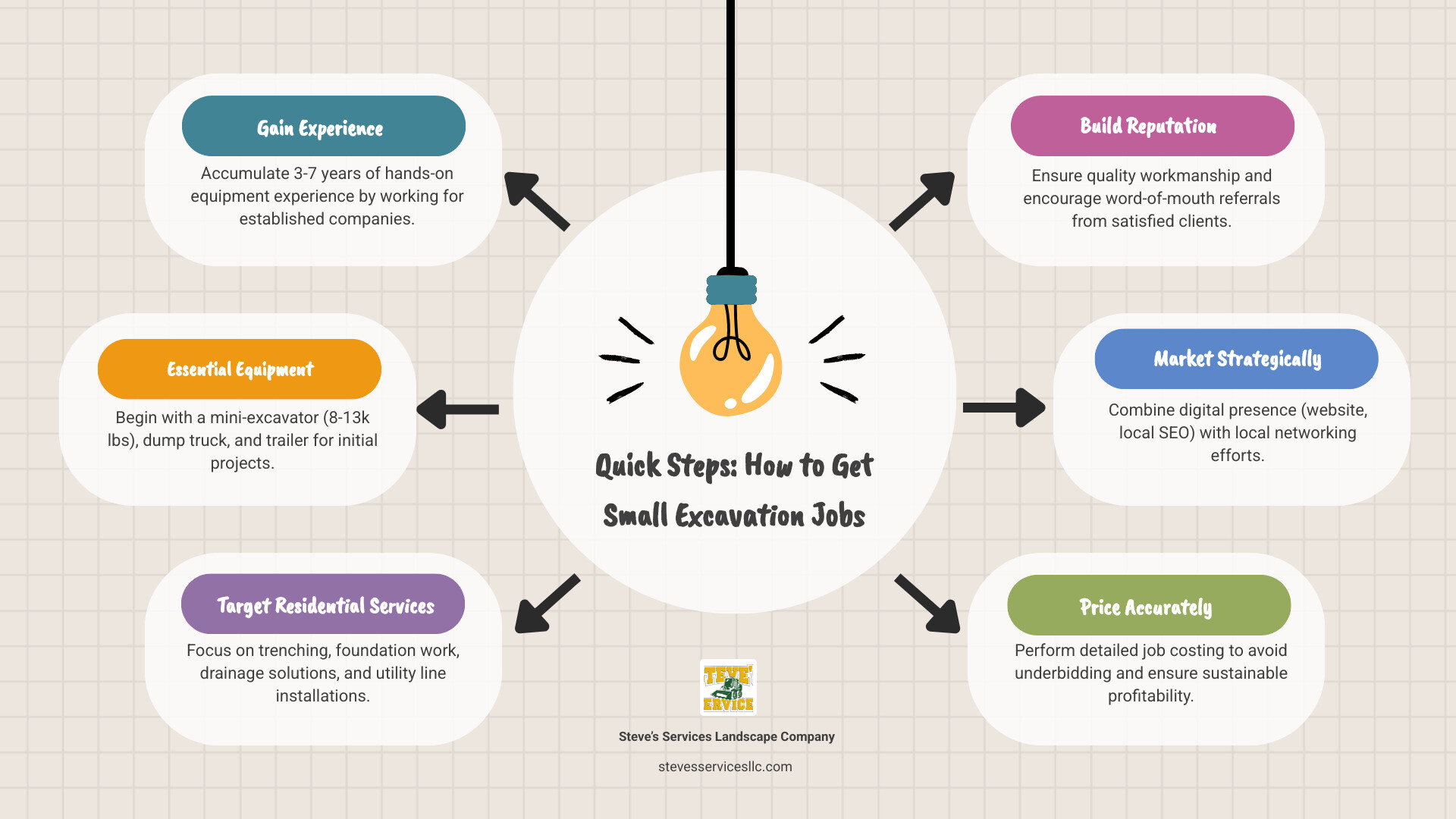

Quick Steps to Get Small Excavation Jobs:

- Gain 3-7 years of hands-on equipment experience working for established companies

- Start with essential equipment – mini-excavator (8-13k lbs), dump truck, and trailer

- Target residential services – trenching, foundation work, drainage, and utility lines

- Build your reputation through quality work and word-of-mouth referrals

- Market strategically using both digital presence and local networking

- Price accurately to avoid the common pitfall of underbidding jobs

The beauty of small excavation work lies in its accessibility and profitability. Unlike massive commercial projects requiring extensive bonding and enormous equipment investments, small jobs allow you to build experience, develop client relationships, and generate steady cash flow with manageable startup costs.

Many successful contractors started exactly where you are now. As one forum contributor noted, “I have a friend with a full-time job who does small projects on the side using a 3-ton mini excavator, small dozer, and small loader tractor, staying busy through word-of-mouth.” This proves that specialized focus on smaller projects can create sustainable income while you develop your skills and business acumen.

The key is understanding that small excavation jobs aren’t just stepping stones – they’re often more profitable per hour than larger projects due to reduced competition and higher margins on specialized residential work like utility trenching, foundation excavation, and drainage solutions.

I’m Steve Sylva, owner of Steve’s Services, and over my 25+ years in the landscape and excavation industry, I’ve learned that understanding how to get small excavation jobs is crucial for building a sustainable contracting business. My experience has shown that starting with smaller residential and commercial projects allows you to perfect your craft while building the reputation and capital needed for future growth.

How to get small excavation jobs terms at a glance:

Step 1: Laying the Groundwork for Your Excavation Business

Starting any business requires a solid foundation, and small excavation is no exception. Before we even think about digging, we need to ensure our business is set up correctly, legally compliant, and financially sound. This initial planning phase is crucial for long-term success and avoiding common pitfalls. As the saying goes, “If you fail to plan, you should plan to fail.”

Foundational Legal and Safety Requirements

The first step in understanding how to get small excavation jobs is to ensure you’re operating within the law and, more importantly, safely. This involves several critical components:

- Business Registration and Legal Structure: We need to decide on our business’s legal structure, whether it’s a Sole Proprietorship, LLC (Limited Liability Company), or Corporation. For many small excavation businesses, an LLC offers a good balance of personal liability protection and operational simplicity. After choosing, we’ll need to register our business with the state and obtain any necessary local permits in our service areas like Burlington, MA, Everett, MA, or Danvers, MA.

- Insurance Policies: This is non-negotiable. We’ll need comprehensive general liability insurance to protect against property damage or injuries that might occur during our work. For any employees, workers’ compensation insurance is also essential. Some forum discussions indicate that digging coverage alone can cost anywhere from $3,000 to over $9,000 per year, with general business insurance potentially adding another $500 to $1,500 per month. These are average costs based on internet data and not actual costs for Steve’s Services. Without proper insurance, a single accident could derail our entire business.

- Safety Standards (OSHA and Beyond): Excavation work is inherently hazardous. We must strictly adhere to OSHA (Occupational Safety and Health Administration) guidelines for trenching and excavation. This includes proper trench shoring, slope stabilization, and ensuring all our team members wear appropriate Personal Protective Equipment (PPE) like hard hats, safety vests, and steel-toed boots. As one experienced contractor put it, “Most accidents in the excavation business do not require a band-aid.” This humor underscores a serious point: excavation accidents can be catastrophic.

- Utility Locating Services (Call 811): Before any digging commences, we must call 811, the national “Call Before You Dig” hotline. This free service helps locate buried utility lines (gas, water, electric, communication) in our work area. Hitting a utility line is not only incredibly dangerous but also extremely costly. As one forum user highlighted, “When digging around utilities, it could take all day to find them.” This emphasizes the time and care required to ensure safety around existing infrastructure.

Creating a Solid Business and Financial Plan

With legalities and safety covered, our next step is to draft a robust business and financial plan. This isn’t just a formality; it’s our roadmap to profitability.

- Market Research and Service Offerings: We need to understand our local market. Who are our potential clients in Medford, MA, or Saugus, MA? What types of small excavation services are most in demand in our communities? Are there specific niches we can fill, like specialized drainage solutions or tight-site residential work?

- Startup Costs and Operating Budget: A clear picture of our financial needs is crucial. This includes initial equipment purchases (or rentals), insurance premiums, fuel, maintenance, marketing, and administrative costs. While one forum thread discussed starting with $40,000, experienced contractors often point out that essential equipment like a decent excavator and tandem dump truck alone can cost anywhere from $150,000 to over $450,000 (average costs based on internet data and not actual costs for Steve’s Services). This highlights the need for careful financial planning.

- Pricing Strategy and Profit Projections: This is where we determine how to make money. We need to develop a competitive pricing strategy that covers all our costs (labor, equipment, fuel, materials, overhead) and ensures a healthy profit margin. We’ll project our potential revenue and expenses to understand our profitability.

- Securing Financing: Unless we have significant personal savings, we’ll likely need financing. This could involve small business loans, lines of credit, or even partnerships with investors. A comprehensive business plan is essential when approaching lenders. As one expert advised, “Being able to wisely borrow is essential to a business’s successful growth.” It’s also wise to maintain at least three months of operating savings in the bank as a general rule.

Step 2: Gearing Up: Equipment Decisions for Small Jobs

Once our business foundation is solid, we get to the fun part: choosing our equipment. This decision shapes everything about our business – the jobs we can take, how efficiently we work, and ultimately, how much money we make. Getting this right is crucial for understanding how to get small excavation jobs and completing them profitably.

For small excavation work, compact equipment is king. A mini-excavator in the 8,000-13,000 pound range often becomes the heart of our operation. These machines are perfect for trenching utility lines, digging foundations for home additions or sheds, and tackling stump removal projects. What makes them special is their ability to squeeze into tight residential spaces – something that’s incredibly valuable when working in established neighborhoods around Melrose, MA, or Stoneham, MA.

Skid steers and compact track loaders bring incredible versatility to our toolkit. They excel at grading driveways, clearing small parcels of land, moving materials around job sites, and even handling light demolition work. When paired with a reliable dump trailer for hauling away spoils and bringing in materials, these three pieces form a powerful foundation for any small excavation business.

Don’t forget about the extras that make these machines truly shine. Various attachments can transform a single piece of equipment into multiple specialized tools. Trenching buckets, hydraulic hammers, grapples, and brush cutters all expand what we can accomplish on a job site.

Of course, we need to budget for the ongoing costs too. Maintenance, fuel, and repairs are part of the business, and smart contractors factor these into their pricing from day one. For those interested in learning more about versatile equipment options, our Bobcat Services page shows how these machines can tackle diverse projects.

Just to give you an idea of the investment involved, backhoes can cost between $18k-$100k depending on age, condition, and features. These are average costs based on internet data and not actual costs for Steve’s Services.

To Buy or To Rent? Making the Right Choice

Here’s the million-dollar question that keeps new contractors up at night: should we buy or rent our equipment? Both options have their place, and the right choice depends on our startup capital, expected workload, and long-term vision.

| Factor | Pros of Renting | Cons of Renting | Pros of Buying | Cons of Buying |

|---|---|---|---|---|

| Upfront Cost | Low initial investment | N/A | Build equity over time | High initial capital required |

| Maintenance | Typically included | N/A | Full control over maintenance | All repair costs on you |

| Availability | Always get working equipment | May not be available when needed | Always available | Downtime during repairs |

| Long-term Value | No equity built | Higher cost over time | Asset that retains value | Depreciation risk |

| Tax Benefits | Immediate expense deduction | N/A | Depreciation deductions | More complex tax implications |

Renting makes sense when we’re just starting out, testing the waters, or handling seasonal work. It keeps our cash flow flexible and lets us try different equipment types before committing to a purchase. The downside? Rental costs add up quickly, and we’re building someone else’s equity instead of our own.

Buying becomes attractive once we have steady work lined up. We build equity, have complete control over maintenance schedules, and never worry about equipment availability during busy seasons. The challenge is the significant upfront investment and the responsibility for all repairs and maintenance.

Many successful contractors start with a hybrid approach – renting initially while building their client base, then purchasing their most-used equipment once cash flow stabilizes.

Sourcing Your Equipment

When we’re ready to acquire equipment, we have several paths to explore. New equipment offers the latest technology, full warranties, and that confidence that comes with being the first owner. However, it also comes with the highest price tag and steepest depreciation curve.

Used equipment often provides the sweet spot for small contractors. We can get quality machines at a fraction of new prices, especially if we’re willing to accept some cosmetic wear. The key is knowing what to look for and having a trusted mechanic inspect any potential purchase.

Dealerships offer financing options, trade-in programs, and ongoing service relationships. They typically provide some level of warranty even on used equipment. Private sellers might offer better prices but require more due diligence on our part.

Equipment auctions can yield great deals, but they’re also risky. We need to know exactly what we’re looking at and be prepared to make quick decisions. Lease-to-own programs split the difference, offering lower initial costs with a path to ownership.

Regardless of where we buy, thorough inspection and maintenance records are non-negotiable. A machine that looks good but has been poorly maintained will cost us far more in the long run than a well-cared-for piece with some honest wear.